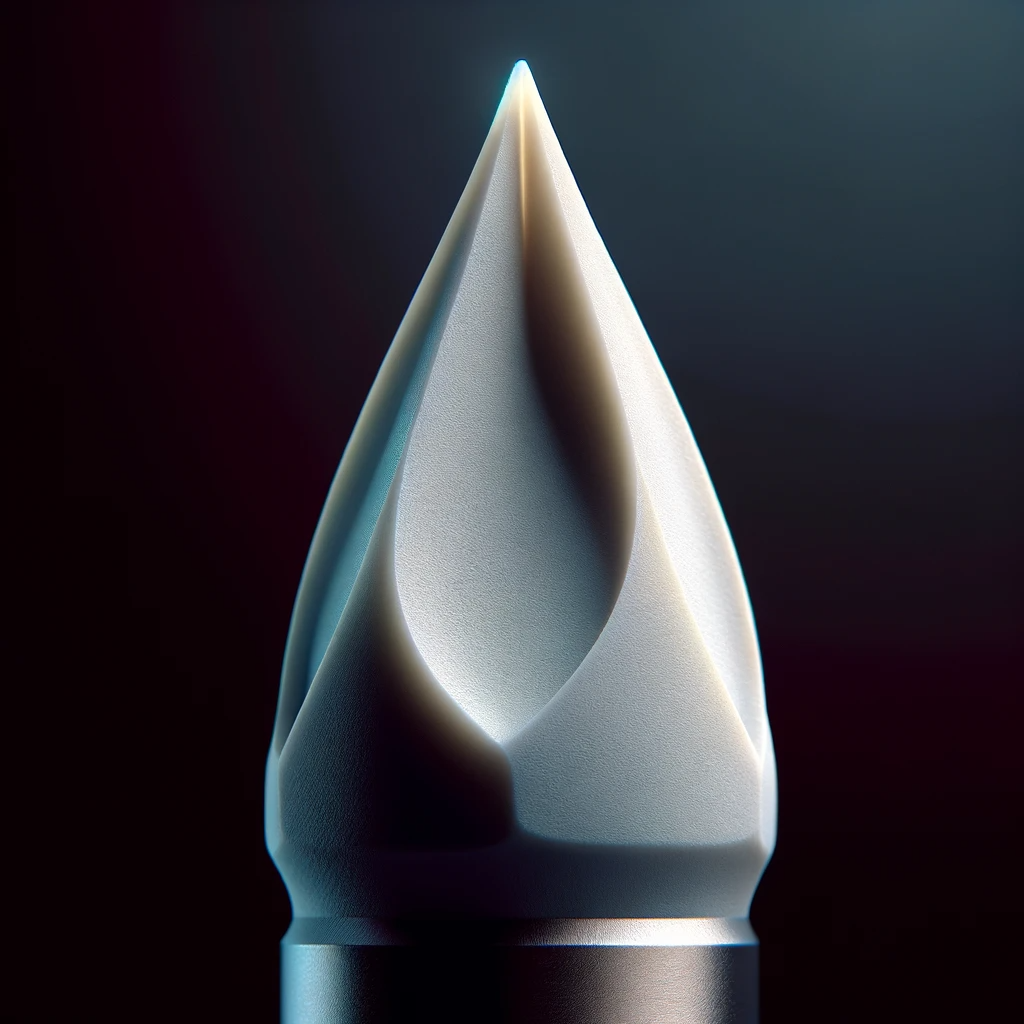

With skilled engineering and planning, ceramic 3D printing can produce ceramic parts with optimal properties and geometries that were once considered unachievable. As a manufacturing partner, SINTX’s strength lies in combining the unique properties of technical ceramics with the flexibility of 3D printing to engineer high-performance ceramic parts and prototypes that outperform alternative materials. Our proprietary, lithography-based approach to ceramic 3D printing significantly shortens manufacturing times for ceramic components, providing clients with a competitive edge through these pathways:

- Elimination of Tooling Time

- Elimination of Mold Construction

- Shortened Development Cycles

- Geometric Design Freedom

- Elimination of Machining Needs

- Rapid/Parallel Design Iterations

- Accelerated Time to Market

SINTX offers ceramic 3D printing services precisely tailored to your business’s unique needs. Our partnership begins with a focused understanding of your objectives, ensuring our advanced solutions align seamlessly with your goals. From conceptualization to final production and quality control, our team is committed to providing comprehensive support. Partner with SINTX for a collaboration that transforms your ideas into tangible, high-quality ceramic products.

CONTACT US